MIL-PRF-9117E

4.2 First article inspection First article testing shall be accomplished using two

.

containers of adhesive (see 3.1). One container shall be used to prepare and test

specimens in accordance with paragraphs 4.4.3 and 4.4.5. The second container shall be

used for storage stability testing in accordance with paragraph 4.4.4. Failure to pass any

examination or test shall be cause for rejection of the first article.

4.3 Conformance inspection Conformance testing shall be accomplished using two

.

containers of adhesive representative of each lot or order. Unless otherwise specified, a

lot shall consist of all adhesive manufactured at one time from one batch, forming part of

one contract or order, and submitted for inspection at the same time and place. One

container shall be used to prepare and test specimens in accordance with paragraphs 4.4.3

and 4.4.5. The second container will be used for storage stability testing, paragraph 4.4.4.

Failure of any sample to pass any examination or test shall be cause for rejection of the lot

or order.

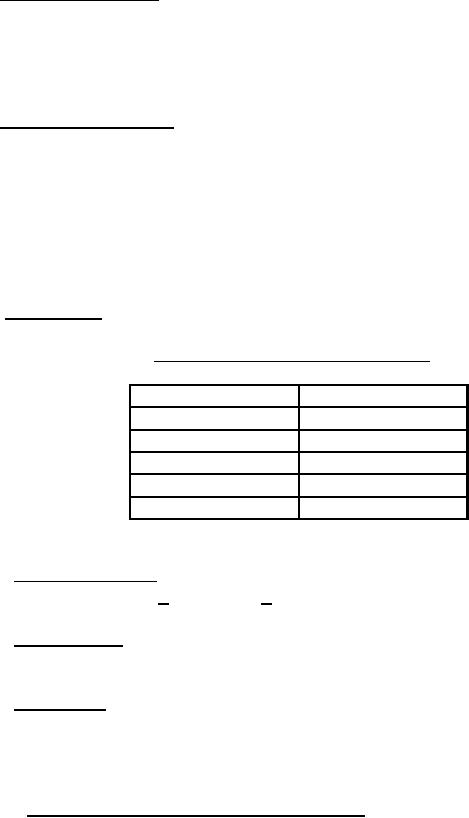

4.4 Test methods.

RequirementsCross-Reference Matrix

REQUIREMENT

VERIFICATION

3.4.1

4.4.3.2

3.4.2

4.4.3.3

3.4.3

4.4.4.2

3.5

4.4.5.2

3.6

4.4.4.1

4.4.1 Standard conditions Standard conditions during the make-up of samples and

.

during air cure shall be 77 2°F, and 50 + 5 % relative humidity.

+

4.4.2 Test specimens The standard NBR-H stock used for tests shall conform to AMS

.

3217/1A or equivalent material as certified by the supplier.

4.4.3 Bond testing. Nine samples will be prepared using

unaged adhesive as described in

paragraph 4.4.3.1. Three will be strip-back tested per paragraph 4.4.3.2 after 4 hours cure

time, three will be strip-back tested per paragraph 4.4.3.2 after 24 hours cure time and

three will be strip-back tested after immersion in aromatic fuel, paragraph 4.4.3.3.

4.4.3.1 Specimen preparation bond for strength testingThe standard NBR-H stock sheet

.

shall be cut into 1 1/2 inch by 6 inch strips and washed with a suitable solvent. Buffing of

the strips will not be allowed. After the strips have dried, apply two coats of adhesive

with wait times per manufacturer's recommendations. The adhesive shall be allowed to air

cure as specified by the manufacturer, and then reactivated with the manufacturer's

recommended solvent. The reactivated surfaces shall be placed together within one

minute and appropriate pressure applied in accordance with the manufacturer's

4

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business