MMM-A-1617B

manufacture, unless approved by the activity responsible for qualification

(see 6.3).

3.2.3 Toxicity. The adhesive shall have no adverse effect on the

health of personnel when used for its intended purpose. Questions pertinent

to this effect shall be referred by the contracting activity to the

appropriate departmental medical service who will act as adviser to the

contracting agency. The manufacturer at time of qualification shall certify

that the adhesive contains no substance known to be toxic to the user under

normal conditions of use. Material safety data sheets shall be prepared and

submitted in accordance with FED-STD-313, one copy of which shall be forwarded

to the preparing activity of the specification and one copy to the qualifying

laboratory.

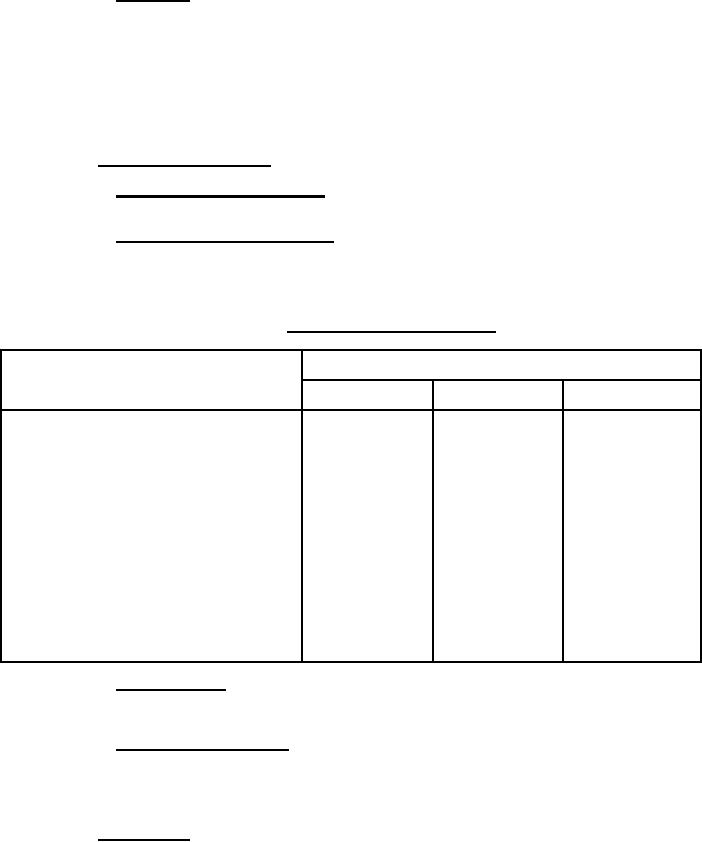

Physical properties.

3.3

3.3.1 Strip adhesion strength. The strip adhesion strength of the

adhesives shall conform to table I when tested as specified in 4.6.2.

3.3.2 Dead load (Type II only). Type II adhesives, when tested as

specified in 4.6.3, shall be capable of supporting a dead load of 0.9 kg (2

lbs) with no more than 1.27 cm (0.5 inch) creep or separation along the

adhesive layer. Only a cohesive mode creep within the adhesive layer shall be

acceptable.

Strip adhesion strength.

TABLE I.

Requirement

Test

Type I

Type II

Type III

As received kg. (lb.) min.

Aluminum to duck

5.4 (12)

6.8 (15)

4.5 (10)

Aluminum to polychloroprene

---

6.8 (15)

---

Aluminum to vinyl

---

---

3.6 (8)

After immersion kg. (lb.) min.

Aluminum to duck (water)

2.7 (6)

5.4 (12)

2.3 (5)

Aluminum to duck (oil)

---

5.4 (12)

3.6 (8)

---

---

Aluminum to duck (fuel)

3.6 (8)

After bond aging kg. (lb.) min.

Aluminum to duck

5.4 (12)

6.8 (15)

4.5 (10)

After accelerated storage kg.

(lb) min.

Aluminum to duck

4.5 (10)

5.4 (12)

3.6 (8)

3.3.3 Brushability. Adhesives shall be readily brushable. They shall

flow easily, spread evenly, and cover the surface adequately when applied as

specified in 4.6.4.

3.3.4 Accelerated storage. Adhesives stored as specified in 4.6.5

shall show no deterioration, gelling, settling, or separation of phases which

cannot be readily dispersed by manual stirring. After storage, they shall

meet the brushability requirements of 3.3.3 and strength requirements of

"after accelerated storage" in table I.

3.4

Shelf life.

The adhesives as furnished by the manufacturer shall

4

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business