MMM-A-1617B

Sampling and inspection.

4.4.2

4.4.2.1 Physical properties. Two samples, taken from two different

containers, of not less than 2 pints each or an amount sufficient for all

testing shall be taken at random from each lot and tested to the requirements

in 4.4.3.1.

*

4.4.2.2 Packaging. The sample unit shall be one shipping container

fully prepared for delivery except that it shall not be palletized and need

not be sealed. Samples for packaging inspection shall be selected in

accordance with MIL-STD-105, Inspection Level S-2.

4.4.3

Quality conformance tests and examinations.

*

4.4.3.1 Physical properties. Each sample selected in accordance with

4.4.2.1 shall be tested for strip adhesion, as received (aluminum to duck)

(4.6.2.3.1) and brushability, as received (4.6.4). In addition, Type II

adhesive shall be subjected to the dead load test (4.6.3). The lot shall be

rejected if a specimen fails any of the above tests.

4.4.3.2 Packaging inspection. Samples selected in accordance with

*

4.4.2.2 shall be visually examined to all the requirements in section 5 of

this specification. Defects shall be defined in accordance with table II.

The lot size shall be the number of shipping containers in the lot. There

shall be no defects.

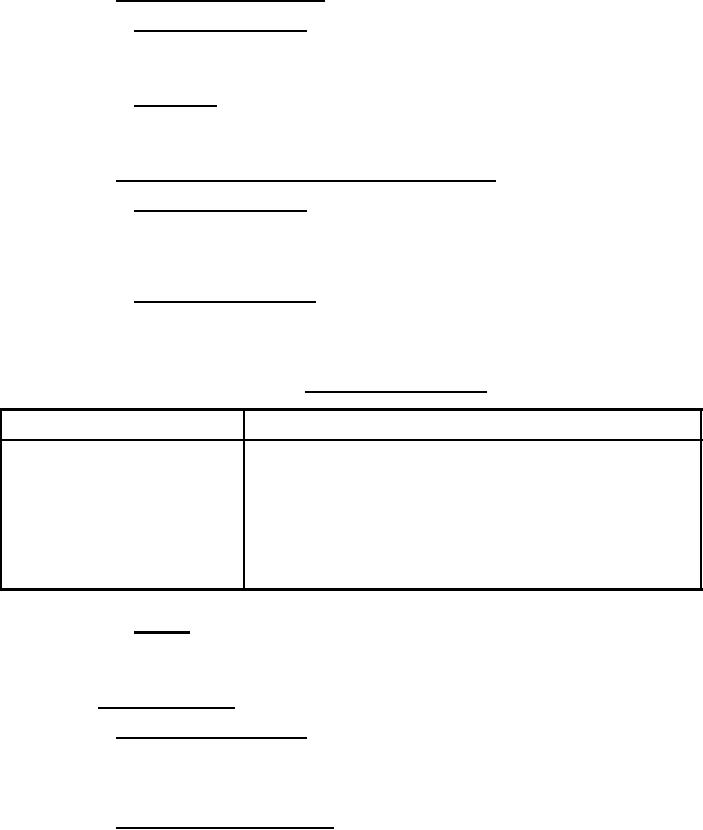

TABLE II.

Packaging inspection.

Examine

Defect

Packaging

Container not as specified, closures not

accomplished by specified or required methods or

materials. Puncture, break, leakage or seepage

of contents. Nonconforming component, component

missing, damaged or otherwise defective. Bulged

or distorted container. Fill not as specified.

Marking

Date omitted, illegible, incorrect, incomplete,

or not in accordance with contract requirements.

*

4.4.3.3 Report. Upon completion of the quality conformance inspection,

the Government activity responsible for conducting the inspection program

shall report the results of tests, with recommendations, to the contracting

officer.

4.5

Test conditions.

4.5.1 Specimen conditioning. Unless otherwise specified in the

detailed test method, all specimens and adhesives shall be conditioned at 25°±

3°C

(77°± 5°F) and 50 ± 4 percent relative humidity for a period of 7 days

followed by testing at these conditions.

4.5.2 Application instructions. The adhesive shall be applied in

*

accordance with the following instructions:

a. Clean metal panels with solvent MIL-C-38736, SAE AMS3166 or equivalent.

Dry with clean, lint free cloth. Discard any panel whose surface is

7

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business